Performance Improvement Studies

Cause and Effect Analysis

Visual and Augmented Reality

Emulation

Typical challenges for engineers include:

• Introducing a new product line or machine.

• Increasing performance of an existing line.

• Merging a new line with an existing one.

• Optimising the production schedule.

Typical challenges for engineers include:

• Introducing a new product line or machine.

• Increasing performance of an existing line.

• Merging a new line with an existing one.

• Optimising the production schedule.

Even when the engineer has been around the development spiral and reached a solution, the next challenge presents itself – Communicate and gain acceptance of the design.

Processes along with their resources such as machines, workers, etc. when combined with random events such as breakdowns and variable deliveries of raw material, are not easily presented using spreadsheets and 3D CAD drawings. The missing component is the time dimension as it is this which introduces the variability into the design.

Even when the engineer has been around the development spiral and reached a solution, the next challenge presents itself – Communicate and gain acceptance of the design.

Processes along with their resources such as machines, workers, etc. when combined with random events such as breakdowns and variable deliveries of raw material, are not easily presented using spreadsheets and 3D CAD drawings. The missing component is the time dimension as it is this which introduces the variability into the design.

Loxcius combines a systems engineering approach with industry leading discrete event simulation software to create a model that simulates/emulates your processes.

Discrete event simulation has been forged through the modelling of manufacturing processes with time. It has evolved in to what is arguably the most dynamic way with which to:

- Understand a system’s inner workings.

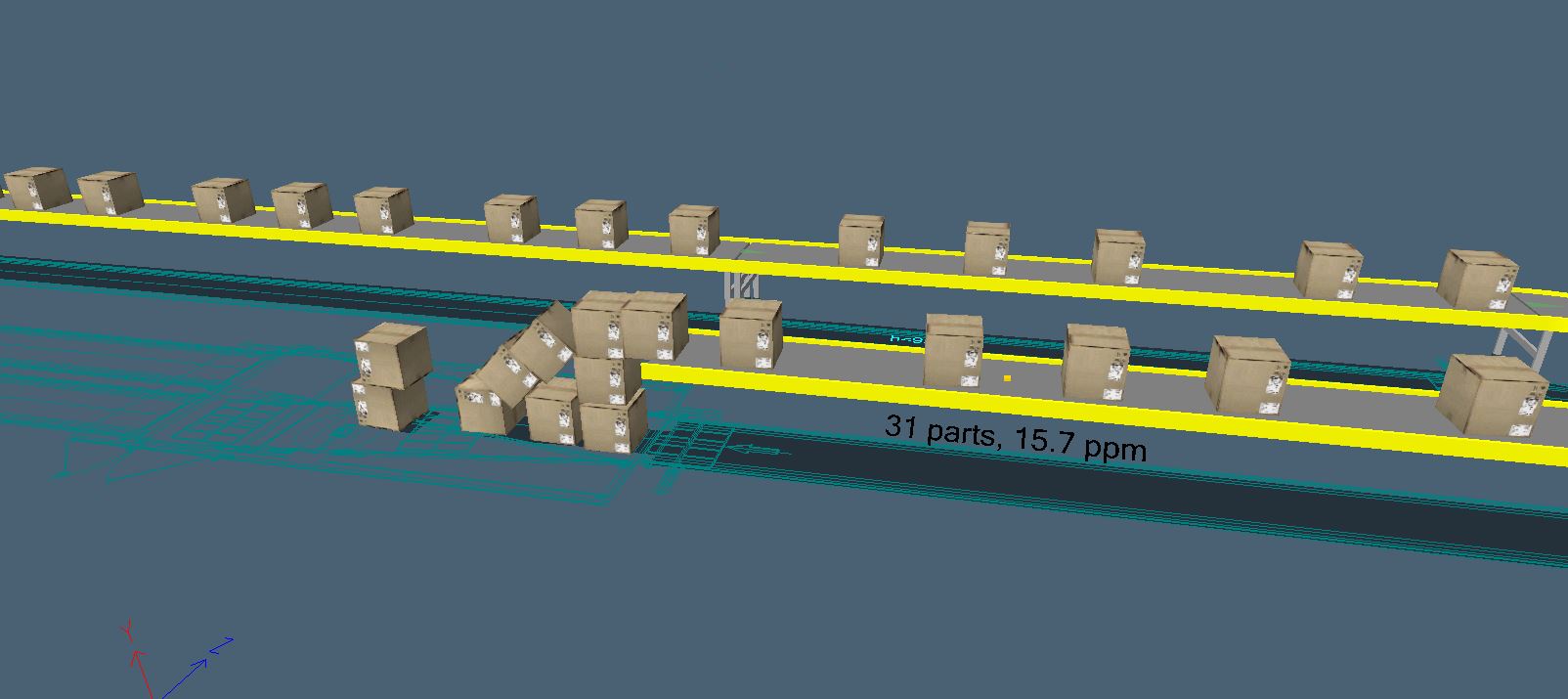

- Identify the core problems, effects and bottlenecks.

- Develop solutions.

- Speed up commissioning times.

- Support the decision making process.

- Asking the questions in order to map the process and produce a conceptual As-Is model.

- Analyse the input data for process times, constraint and resource issues.

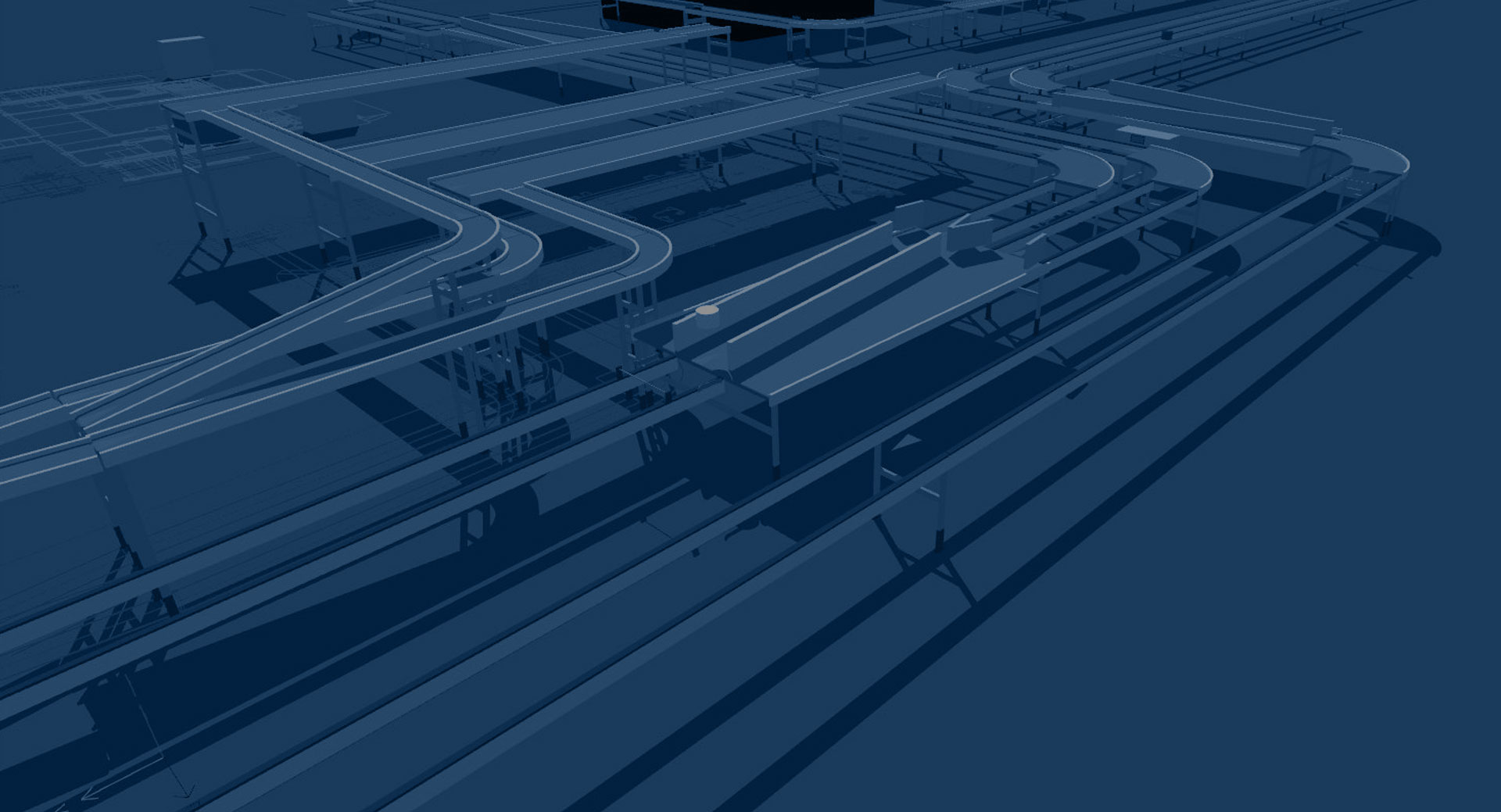

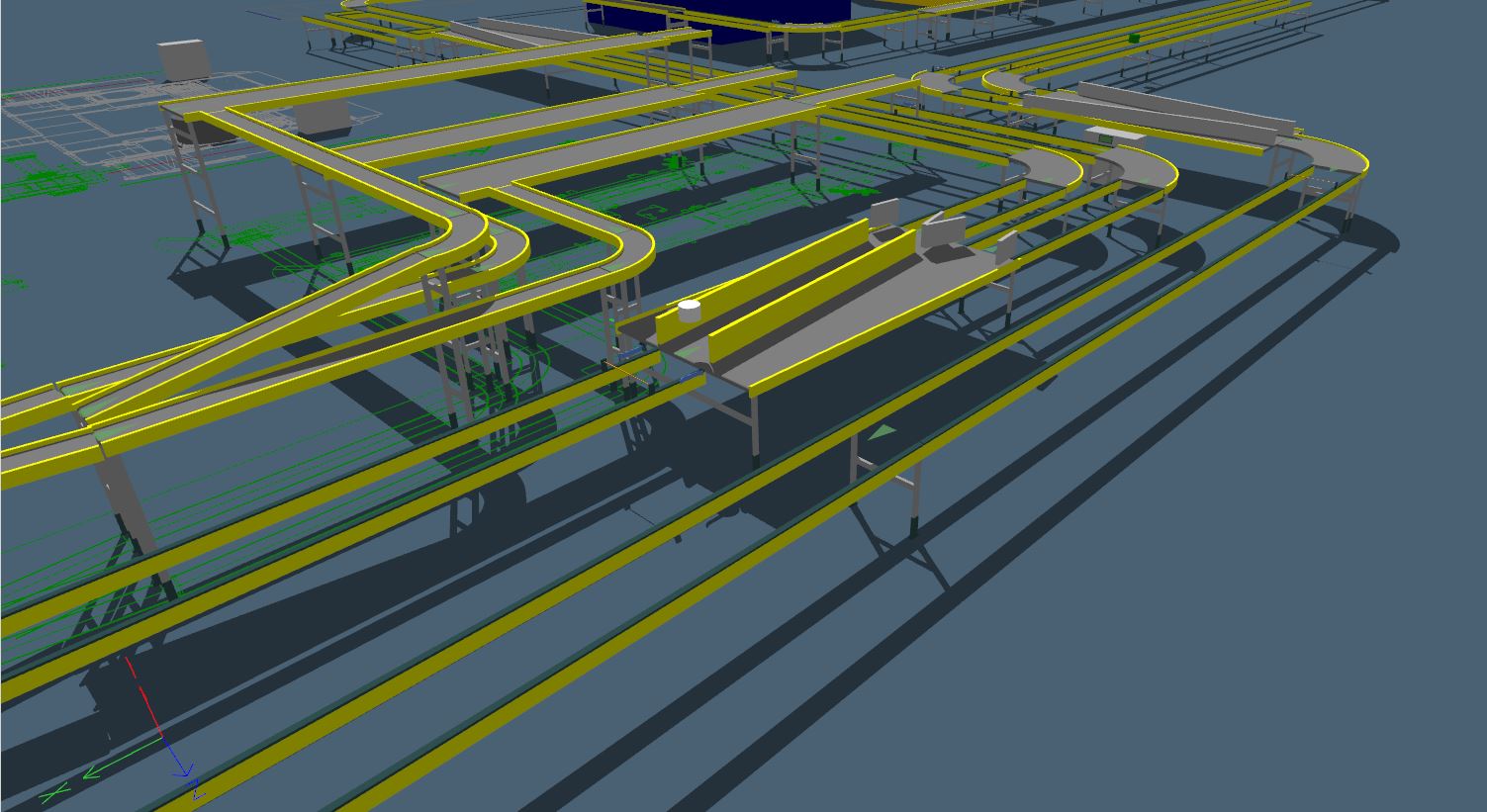

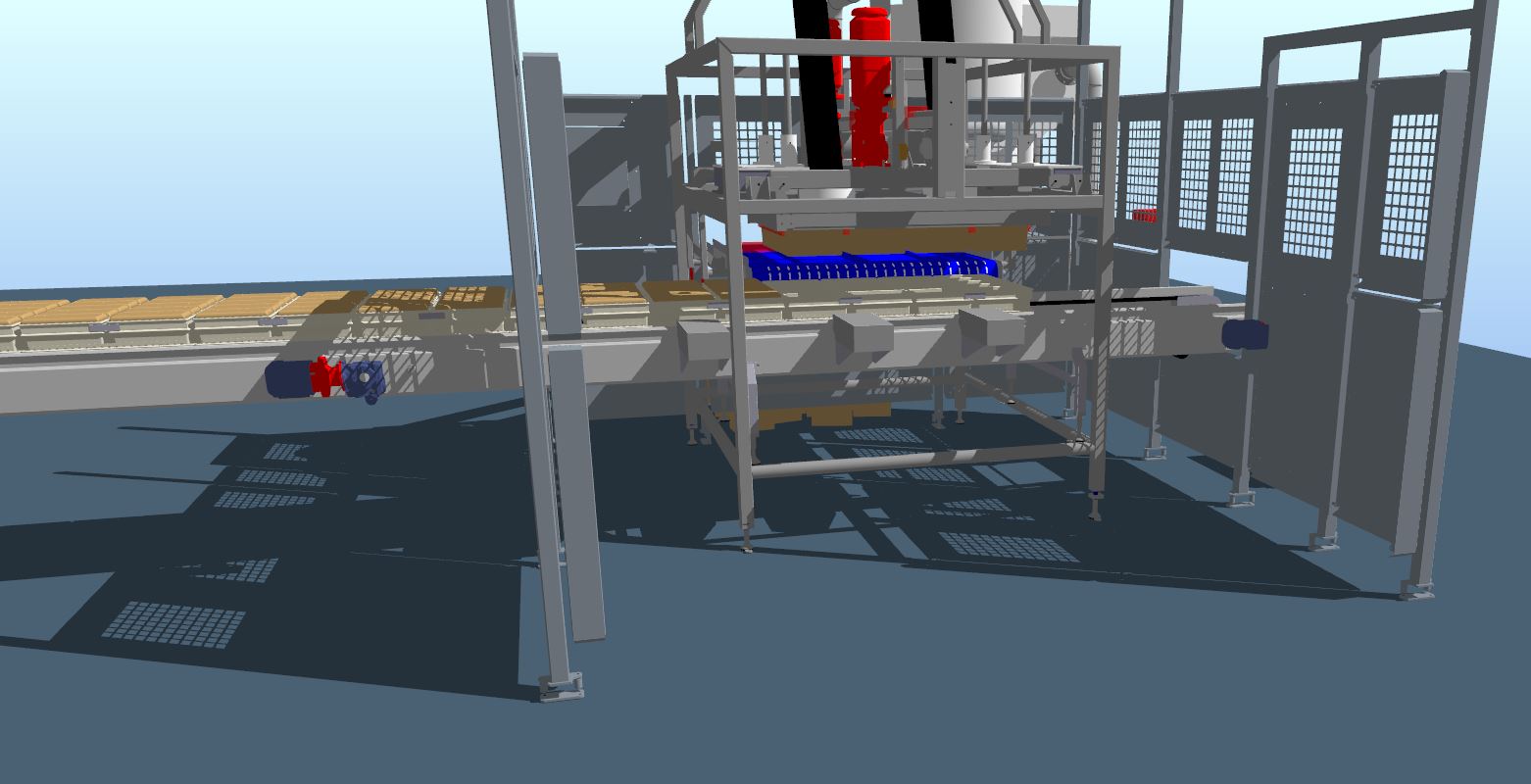

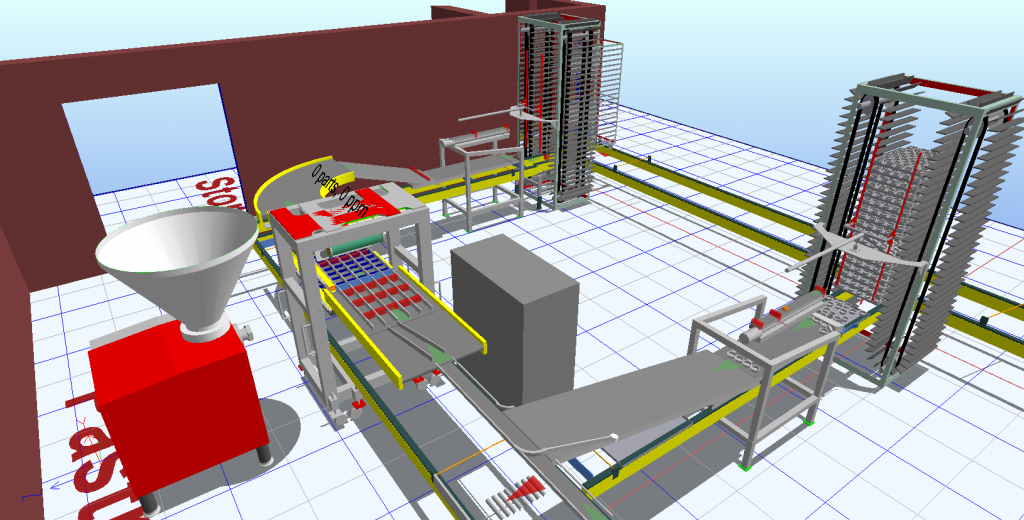

- Import or model 3D symbolic representations of the actual key objects such as machines, conveyors, workers.

- Build the As-Is discrete event simulation model with visually rich animation.

- Verify and support the validation of the model with historic data or peer review

- Support the failure mode, effect, cause and analysis studies through:

- Developing scenarios.

- Identifying additional KPI’s.

- Interaction with the running model.

- Assist or carry out what-if scenarios in order to:

- Evaluate alternative solutions

- Determine the robustness of the design.

- Define the To-Be solution.

- Allow sequential activities such as controls testing to begin sooner and in parallel with other activities.

Loxcius combines a systems engineering approach with industry leading discrete event simulation software to create a model that simulates/emulates your processes.

Discrete event simulation has been forged through the modelling of manufacturing processes with time. It has evolved in to what is arguably the most dynamic way with which to:

- Understand a system’s inner workings.

- Identify the core problems, effects and bottlenecks.

- Develop solutions.

- Speed up commissioning times.

- Support the decision making process.

- Asking the questions in order to map the process and produce a conceptual As-Is model.

- Analyse the input data for process times, constraint and resource issues.

- Import or model 3D symbolic representations of the actual key objects such as machines, conveyors, workers.

- Build the As-Is discrete event simulation model with visually rich animation.

- Verify and support the validation of the model with historic data or peer review

- Support the failure mode, effect, cause and analysis studies through:

- Developing scenarios.

- Identifying additional KPI’s.

- Interaction with the running model.

- Assist or carry out what-if scenarios in order to:

- Evaluate alternative solutions

- Determine the robustness of the design.

- Define the To-Be solution.

- Allow sequential activities such as controls testing to begin sooner and in parallel with other activities.

To download an article on Manufacturing Solutions with DES please click the download button below.

To learn more about simulation and hear how Loxcius can support your project or visualise your line through virtual reality Contact Us.

We understand that the delivery of plans may be core to an organisations operations, therefore our services can be tailored to facilitate the development of a client based in-house capability and facilitate training as part of a larger staff continual professional development programme. To discuss this approach further please Contact Us.

To learn more about simulation and hear how Loxcius can support your project or visualise your line through virtual reality Contact Us.

We understand that the delivery of plans may be core to an organisations operations, therefore our services can be tailored to facilitate the development of a client based in-house capability and facilitate training as part of a larger staff continual professional development programme. To discuss this approach further please Contact Us.